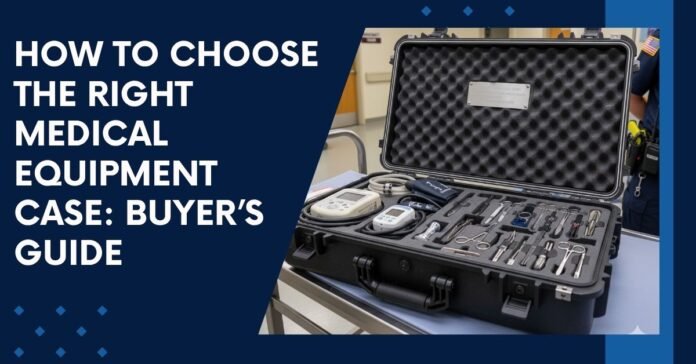

From hospital operating rooms to emergency response vehicles, the safe transport and storage of medical devices are critical. Every piece of equipment—whether a delicate diagnostic instrument, portable ventilator, or surgical tool relies on secure containment to maintain function, sterility, and compliance.

Medical equipment cases are more than containers; they are engineered systems designed to protect, organize, and extend the life of medical devices. In the United States, where patient safety and regulatory standards are paramount, the choice of a medical equipment case can directly impact operational reliability and compliance with FDA and ISO requirements. This guide explains how to choose the right medical equipment case based on materials, safety standards, environmental conditions, and 2025’s most important innovations—so you can make an informed, regulation-ready purchase.

1. Key Functions of Medical Equipment Cases

A well-designed medical equipment case performs multiple protective and logistical roles. Beyond simple transport, cases are built to ensure:

- Shock and impact resistance – Critical for sensitive devices such as endoscopes or imaging sensors.

- Temperature and humidity control – Protects reagents, pharmaceuticals, and instruments sensitive to environmental changes.

- Sterility and contamination prevention – Smooth, sealed interiors and antimicrobial surfaces reduce infection risk.

- Organization and accessibility – Custom foam inserts or modular trays ensure fast access in high-pressure situations.

- Portability and ergonomic use – Lightweight materials, handles, and wheels improve mobility across hospital departments or field environments.

U.S. Regulations, Compliance & Safety Standards

Medical equipment cases are often classified as device accessories under the U.S. Food and Drug Administration (FDA), making compliance non-negotiable.

Key standards and agencies to know:

- FDA Labeling Requirements (21 CFR Part 801): Any claims regarding sterility, protection, or medical use must be accurate and verifiable.

- ISO 13485: International standard for quality management systems in medical device manufacturing. Cases made under ISO-certified facilities ensure consistent production quality.

- ASTM Standards (e.g., ASTM D4169): Define test procedures for drop, vibration, and compression resistance in transport packaging.

- UL and IEC Safety Certifications: Apply to cases containing electronic or powered components.

Compliance not only satisfies regulators but also reduces liability and ensures smooth audits in hospital procurement processes.

Ensuring Reliable Case Performance in Any Environment

Medical cases face widely varying operational environments—from air transport to disaster relief zones. Buyers should evaluate:

- Temperature control: Temperature-controlled medical cases with thermal insulation or active cooling elements support vaccine and biologic transport.

- Humidity resistance: Gasket-sealed designs prevent corrosion and equipment degradation.

- Ruggedness for field use: Reinforced corners and waterproof ratings (e.g., IP67) are essential for outdoor or EMS applications.

- Air freight durability: Lightweight yet impact-resistant materials reduce shipping costs while maintaining safety.

Design & Customization Options

Modern buyers expect more than generic enclosures—custom design and modularity now define the standard for professional medical cases.

Customization features include:

- Custom foam cutouts for specific devices, instruments, or tubing layouts.

- Modular compartments for reconfigurable transport of multiple instruments.

- Handles, wheels, and locking mechanisms to simplify mobility.

- Integrated labeling systems such as QR codes or barcodes for easy tracking.

- RFID and smart tracking for asset management across hospital networks.

Color-coding and branding also enhance visual identification—critical in multi-department medical operations.

6. Cost, Lifecycle & Total Cost of Ownership

While low-cost imports may seem attractive, the true cost of ownership depends on durability, compliance, and service life.

Factors affecting total cost:

- Material longevity – Cases built from reinforced ABS or aluminum may last 5–10 years with minimal maintenance.

- Maintenance requirements – Easy-to-clean surfaces and replaceable foam inserts lower upkeep costs.

- Warranty coverage – pelican cases often include longer warranties and parts support.

- Downtime risk – Equipment damage from poor case quality can lead to costly operational interruptions.

Investing in durable, compliant designs yields a measurable ROI for hospitals and medical manufacturers through reduced replacement cycles and improved device safety.

How to Choose the Right Case: 10-Point Buyer Checklist

Before selecting a supplier or model, review these core criteria:

- Device type and sensitivity – Start by identifying what the case will protect—whether it’s a portable ultrasound, ventilator, or set of surgical tools. The level of shock absorption, insulation, and sealing should align with the device’s fragility and value.

- Compliance requirements – Always confirm that your case meets applicable FDA, ASTM, or ISO standards. This ensures traceability and legal compliance, especially for regulated medical device accessories used in U.S. healthcare settings.

- Material durability – Match the case’s material to the expected lifespan and usage conditions. For example, ABS and aluminum offer long-term protection for daily hospital or field operations, while composite builds are ideal for high-impact environments.

- Weight and portability – Balance strength with usability. Lightweight materials and ergonomic handles reduce strain during frequent transport between departments or facilities. Consider cases with wheels for larger equipment to improve maneuverability.

- Sterility and contamination control – Choose cases with smooth, non-porous surfaces and optional antimicrobial coatings. Sealed interiors and removable liners simplify cleaning and prevent cross-contamination during repeated use in sterile environments.

- Customization level – Evaluate how much internal organization you need—custom foam inserts, removable trays, and modular compartments make a big difference. By choosing an authorized Pelican case dealer in Houston, buyers gain local access to certified customization, warranty support, and case modifications designed for medical environments.

- Environmental resistance – Assess how your case performs under temperature shifts, humidity, and vibration. For outdoor or field applications, look for IP-rated waterproofing and reinforced corners designed for impact resistance.

- Service and warranty – Reliable after-sales support is essential. Ensure the manufacturer or distributor offers clear warranty terms, spare part availability, and responsive customer service for long-term value and peace of mind.

- Cost vs. lifecycle value – Don’t focus solely on the initial purchase price. A more durable, compliant case may cost more upfront but will save money over time by reducing maintenance, repair, and equipment damage costs.

- Aesthetics and usability – Finally, consider how the case will function in daily workflows. Features like color-coding, clear labeling, and ergonomic latches improve organization, efficiency, and professional presentation during transport or deployment.

A structured checklist ensures your chosen protective hard case supports not only the device but also your workflow, compliance, and logistics.

Case Studies & Practical Applications

Emergency Medical Services (EMS):

Field medics rely on rugged, waterproof cases with custom foam inserts to secure trauma kits and defibrillators. Impact resistance and quick access can directly affect patient outcomes.

Hospital Surgical Units:

Sterile transport cases ensure delicate surgical instruments remain contamination-free between operating theaters and sterilization departments.

Telemedicine & Mobile Clinics:

Compact, lightweight medical device cases protect diagnostic equipment during long-distance travel, ensuring power and data cables remain intact.

Disaster Response Teams:

In field conditions, modular, temperature-controlled medical cases enable vaccine distribution and cold-chain integrity in extreme environments.

Making the Right Choice: Ensuring Safe and Compliant Medical Equipment Transport

Selecting the right medical equipment case in the U.S. requires balancing protection, compliance, customization, and cost-efficiency. With healthcare standards constantly evolving and new smart-case innovations emerging, it’s essential to choose a case that meets regulatory requirements while performing reliably in real-world medical environments.

Whether you are outfitting a hospital, EMS fleet, or manufacturing facility, a thoughtfully designed protective case safeguards your equipment and ensures that medical professionals can perform their work effectively. Investing in high-quality cases not only protects valuable devices but also supports patient safety and operational efficiency across all healthcare settings.