When it comes to protecting mission-critical gear, military professionals, defense contractors, and aerospace specialists know there is no room for compromise. Sensitive equipment—from communications systems and weapons to UAVs and medical devices—must remain fully operational in some of the harshest environments on Earth. That’s where military cases with custom foam inserts become indispensable.

Unlike standard consumer-grade cases, MIL-SPEC cases are engineered to withstand extreme impact, vibration, moisture, and temperature shifts. Pairing these rugged shells with precision-cut foam inserts ensures not only durability but also secure organization and easy deployment in the field.

In this comprehensive buying guide, we’ll walk you through everything you need to know about choosing the best military cases with foam inserts. From material selection and foam types to industry applications and future innovations, this resource is designed to help procurement officers, defense professionals, and equipment manufacturers make informed purchasing decisions.

Why Military Cases Need Custom Foam Inserts

Military-grade protective cases are only as good as what’s inside them. While the hard exterior protects against external impact, the foam insert is the first line of defense against internal shock, vibration, and abrasion.

Standard vs. Military-Grade Cases:

- Consumer-grade cases may protect against light travel wear, but they rarely meet MIL-STD-810 compliance, which ensures resistance to water, dust, shock, and temperature extremes.

- Military cases, when paired with foam, provide both exterior ruggedness and interior precision-fit cushioning for delicate gear.

Why Foam Inserts Matter:

- Shock absorption: Prevents damage from drops or vibration in transport.

- Moisture resistance: Closed-cell foams repel water and resist mold/mildew.

- Organization: Custom cut-outs keep each piece of equipment in its place, ensuring rapid deployment when needed.

In short, without precision foam inserts, even the toughest case leaves gear vulnerable.

Key Features to Look for in Military Cases

When evaluating military-grade cases, certain features separate professional-grade products from generic alternatives.

1. Durability & Materials

Look for cases constructed from high-strength polymers (such as polypropylene or polycarbonate) or lightweight aluminum alloys. These materials provide impact resistance, UV protection, and weatherproofing.

- IP ratings (Ingress Protection) measure water and dust resistance. For example, IP67 means the case is waterproof up to 1 meter for 30 minutes.

- Reinforced corners and pressure equalization valves are essential for air transport.

2. MIL-SPEC Certification

Not all “tough-looking” cases are truly military-grade. Verify compliance with MIL-STD-810, which tests cases against drop, shock, vibration, humidity, and salt fog conditions. These certifications provide assurance that the case can withstand real-world battlefield and aerospace environments. Choosing a certified case also streamlines procurement, since many defense contracts require proof of MIL-SPEC compliance.

3. Foam Insert Customization

Foam inserts should be tailored to the exact specifications of your gear. Advanced cutting methods ensure precision:

- CNC machining: Ideal for complex or irregularly shaped equipment.

- Waterjet cutting: Smooth, accurate cuts for delicate gear.

- ESD-safe foam: Prevents static discharge that can damage sensitive electronics.

4. Portability & Weight Considerations

Military operations demand mobility. Choose cases with ergonomic handles, rolling wheels, and manageable weight without sacrificing protection. Lightweight composites can reduce fatigue during long deployments while still maintaining structural integrity. For airborne or rapid-response missions, portability ensures faster loading, unloading, and deployment of critical gear.

5. Locking & Security Options

Security is paramount. Look for:

- TSA-approved locks for air travel.

- Padlock hasps or integrated combination locks for high-value equipment.

- Optional RFID or GPS tracking for supply chain monitoring.

Choosing the Right Foam Inserts for Cases

The foam inside your case determines whether your equipment arrives intact or damaged.

Foam Types

- Polyurethane Foam (PU): Soft, good for lightweight and fragile items.

- Polyethylene Foam (PE): Rigid, dense, ideal for heavier equipment.

- Closed-Cell Foam: Waterproof, chemical-resistant, long-lasting.

- ESD-Safe Foam: Protects electronics from electrostatic discharge.

Precision Cutting Methods

- CNC milling: High precision, repeatable for mass production.

- Die-cutting: Cost-effective for large batches of identical inserts.

- Waterjet cutting: Best for highly complex shapes and clean edges.

Real-World Example

A defense contractor transporting UAVs reported zero equipment failure after switching to custom-cut PE foam inserts in waterproof cases, despite frequent desert deployments with heavy dust exposure.

Applications of Military Cases with Foam Inserts

Military cases with foam inserts are used across defense, aerospace, and industrial fields:

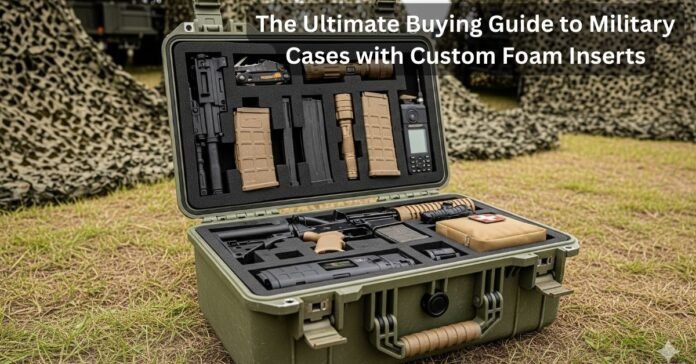

- Tactical Gear & Firearms: Securely store rifles, sidearms, optics, and accessories. Precision-cut foam prevents shifting during transit, while secure compartments allow quick access during missions.

Communications Equipment: Protect radios, satellite systems, and encrypted devices. Foam inserts minimize vibration damage, keeping sensitive electronics calibrated and mission-ready. - UAVs & Drones: Ensure safe deployment and retrieval of unmanned systems. Custom cavities protect propellers, cameras, and control units, reducing the risk of downtime in the field.

- Medical & Aerospace Equipment: Safeguard life-saving devices and avionics during transport. Closed-cell foam resists moisture and contamination, ensuring sterile conditions and operational reliability.

Each application has different foam density and cutout requirements, making customization critical.

Common Mistakes Buyers Make

Even seasoned procurement professionals can make costly errors when sourcing cases. Avoid these pitfalls:

- Choosing based only on price: Cheaper cases often lack MIL-SPEC compliance or proper foam density.

- Ignoring MIL-SPEC ratings: A rugged appearance doesn’t guarantee actual certification.

- Overlooking foam properties: Using the wrong foam type (too soft, too rigid, or not ESD-safe) can render protection ineffective.

Future Trends in Military Cases & Foam Inserts

The defense and aerospace industries are rapidly innovating in protective solutions. Expect to see:

- Smart Foams: Self-healing materials and vibration-dampening nanotechnology. These advanced foams adapt to changing stress levels, extending product lifespan and reducing replacement costs. They also improve protection for sensitive electronics in environments with constant vibration, such as aircraft or armored vehicles.

- Lightweight Composites: Carbon fiber and hybrid polymers reduce weight without compromising strength. Lighter cases mean easier mobility for soldiers and reduced fuel costs in aerospace logistics. Despite their reduced weight, these composites still meet or exceed MIL-STD-810 durability requirements.

- Sustainability: Eco-friendly foam alternatives and recyclable case materials are gaining traction in procurement standards. With governments emphasizing greener defense initiatives, manufacturers are investing in bio-based foams and reusable materials. This shift helps reduce environmental impact without sacrificing mission-critical performance.

Buying Checklist

Before making a purchase, evaluate the following criteria:

- MIL-SPEC certification to ensure compliance with military testing standards.

- Material selection such as polymer or aluminum, matched to the operating environment.

Foam density and type appropriate for the specific equipment being protected. - Waterproof and dustproof protection confirmed by the case’s IP rating.

- Locking and security features designed for mission requirements.

- Portability and weight balance to maintain ease of transport in the field.

Conclusion

When it comes to protecting defense and aerospace equipment, a rugged military case is only half the solution. Pairing it with custom precision foam inserts ensures that sensitive gear remains mission-ready, organized, and shielded from the toughest environments.

By understanding materials, foam types, certifications, and application-specific needs, buyers can avoid costly mistakes and invest in cases that meet the highest standards of performance. Choosing an authorized Pelican case dealer in Texas ensures access to genuine MIL-SPEC certified cases, precision foam customization, and expert guidance tailored to mission requirements.

Frequently Asked Questions (FAQ)

1. What are MIL-SPEC cases?

MIL-SPEC cases are protective cases that meet U.S. Department of Defense testing standards (MIL-STD-810), ensuring durability against shock, vibration, dust, water, and extreme temperatures.

2. Which foam is best for military equipment cases?

Polyethylene (PE) foam is often preferred for heavy, rugged equipment, while polyurethane (PU) foam works better for lightweight or fragile items. ESD-safe foam is essential for electronics.

3. How do I know if a case is truly military-grade?

Look for documented compliance with MIL-STD-810G/H testing, IP ratings, and manufacturer certifications.

🤖 Too Long? Click below AI Option to Summarize The Article: